Are you having problems with bacteria, fungi, algae, or limescale in your well or mains water? The solution is here! Introducing “Top Water,” the cutting-edge water treatment solution with Pulsed Electric Field (PEF) technology.

“Top Water” Key Features

- Antibacterial Efficiency: Destroys bacteria and microorganisms, including the risk of Legionella, through short, high-voltage electrical pulses.

- Scaling Prevention: Transforms calcite into aragonite, preventing annoying limescale buildup and optimizing pipe cleaning.

- Improved Fluidity: Reduces water density, making it more fluid and easier to handle.

Ideal for:

- Hospitals, Nursing Homes, and Food Industries

- Mineral Water Sources and Beverage Industries

- Pharmaceutical, Cosmetic, and Chemical Industries

- Water Treatment Centers and Wastewater Treatment Plants

We offer a complete range of equipment, from mobile solutions for testing Rapid, high-capacity fixed systems:

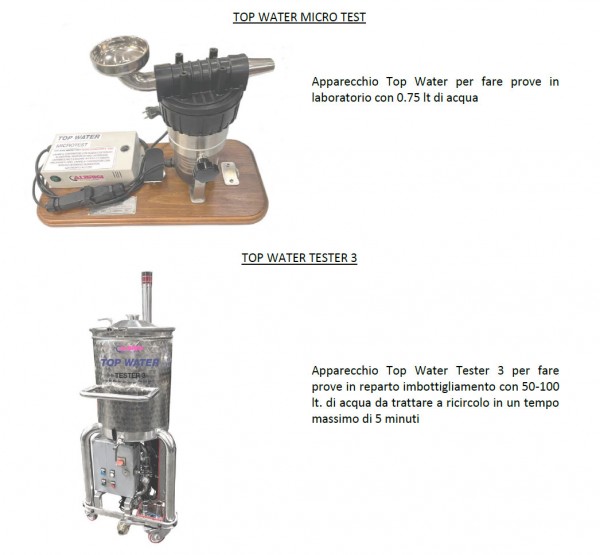

- Microtest (0.75 lt)**: Ideal for rapid laboratory tests.

- Tester 3 (50-100 lt)**: Perfect for direct use in the bottling department.

- Fixed systems (from 5,000 to 100,000 lt/h): Large-scale solutions for continuous and intensive needs.

Patented Technology: Result of an exclusive collaboration with the Swiss company ExtraH2O, specializing in advanced water treatment technologies.

Practical Test and Guaranteed Results:

- We invite you to test “Top Water” directly in your laboratory or production department. We’ll organize a hands-on demonstration, demonstrating the effectiveness of our system in real time.

- Complete documentation of pre- and post-treatment analyses is available upon request.

Don’t waste any more time with ineffective solutions! Contact us today to schedule a demonstration and discover how “Top Water” can improve your water quality.POSSIBLE SERVICES AND OPERATIONS THAT CAN BE PERFORMED WITH TOPTANK-FLY FERMENTERS.

Features:

- qualifies and guarantees perfect contact between the must and skin mass during all processing phases (fermentation/maceration/cryomaceration, etc.)

- perfectly controls the temperature of the various processes (fermentation/cryomaceration, etc.), especially the must-skins mass in the central part of the fermenter, via the thermo-controlled central rotating blade.

- can heat musts with yeasts in the lower part to facilitate their activity.

- can homogeneously and completely cool or heat, and keep the temperature of the entire mass under control at controlled temperatures. Musts—must and skins—and wines—setting temperatures as needed from +35°C to -5°C.

- is designed and specifically for carrying out must treatment operations and processes.

- of crushed grapes—totally natural and innovative wines.

- is specifically designed for experimentation and Research into new, advanced fermentation processes for wineries that want to make extremely high-quality wines and are seeking specific, unique, and above all natural processes to maximize the value of their grapes. These operations are possible with standard accessories.

- Cryomaceration at programmed temperatures without temperature stratification and ensuring homogenization of the crushed white or red grape masses.

- Fermentation of white or red grape musts or crushed grapes.

- Fresh fermentation of white or red grapes, even very dried ones.

- Addition of 10-20-30% of whole, uncrushed grapes during the fermentation of red grapes (superfermentation).

- Fermentation of 1-2-3 different types of crushed red grapes (fermentation blend).

- Refermentation of red wines on existing pomace (double fermentation).

- Temperature-controlled maceration of white or red grapes. Red

- Macerations to make rosé wines

- Preheating musts with yeasts to be cultivated and heated at the bottom of the fermenter

- Blending wines to avoid temperature stratification at the top or bottom of the fermenter

- Blending two or more wines together to create a homogeneous blend

- Blending wine before taking a wine sample and making the mass homogeneous

- Blending wine to dissolve chemicals in the wine

- Continuous blending of wine during sampling for bottling (operations possible with optional accessories)

- Discharging the spent pomace by gravity directly into the press without a gravity pump; Automatic extraction of spent pomace

- Mechanical extraction of grape seeds

- Bâtonnage Programmable over time

- Automatic pumping over of the must

- Tartaric stabilization at -4°C

- Flotation

- Oxygenation of crushed grapes – musts or wines

- Hyper-oxygenation of white musts

- Control and monitor all operations with an iPad or iPhone or remotely from a PC

- Choose a pre-set work program and archive all process data for up to 10 years (10 harvests)

- Set process alarms that alert you to any anomalies during processing

- With a specific conditioning system, it is possible to simultaneously heat the cap of pomace (which is high above the must) to +35°C and cool the must to +10°C (which is low below the cap of pomace), or rather, you can condition both at will. (must/skins) separately

- saturation with inert argon/nitrogen gas

- control of wine, must, or crushed grapes levels

- automatic racking of musts or wines

- programmable automatic washing

- watertight UV sterilizing lamps

- suction of fermentation CO2, fermentation vapors, or fruit flies into the tank and discharges them outside

- remote control and monitoring of levels, temperatures, processes, and set work phases via iPhone, iPad, or PC

- opening and closing of the lower door and activation of valves with radio control

- having a dedicated camera that displays the inside of the fermenter and stores the images in memory

- customized programs for all automatic processes with historical memory stored for 10 years years

AIRSANA is a suction system that absorbs moisture and odors from machinery;

CLEANSYSTEM is an automatic washing system for systems and machinery;

ANOLIN is the latest-generation biological detergent;

INNERGAS is a system that supplies inert nitrogen gas during processing;

WATER SERVICE consists of an installation